Taiwan-CoreTech System Co. Ltd. (Moldex3D) has released the new Moldex3D Digimat-RP for material modeling of reinforced plastics.

Digimat-RP is a unique nonlinear multi-scale structural modeling solution for fiber reinforced plastic parts developed by e-Xstream engineering, a MSC Software company.

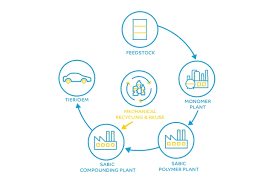

It provides not only an innovative micromechanical modeling approach for optimal and predictive design of composite parts, but also bridges the gap between injection molding and structural simulation analyses, said the company.

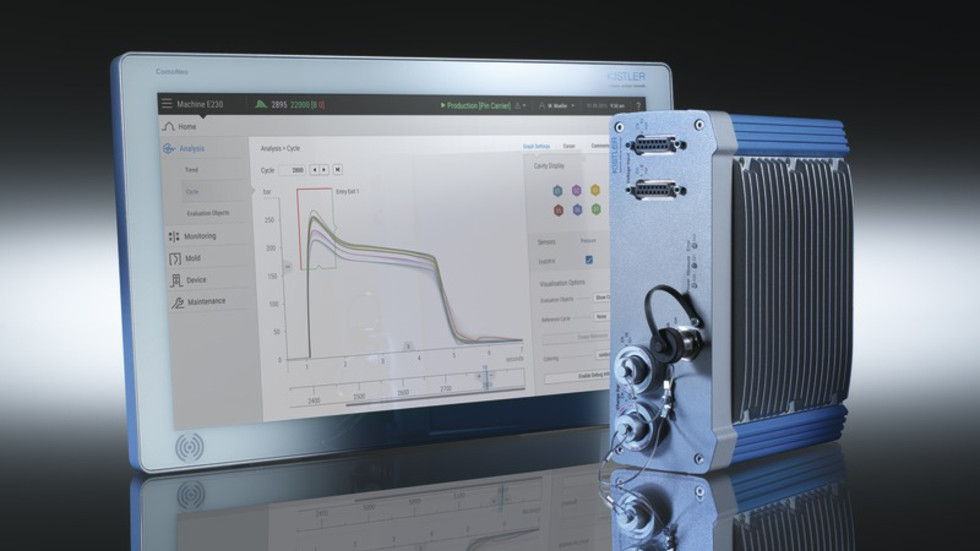

Developed jointly by Moldex3D and e-Xstream, the simulation tool includes process-induced properties, such as local fiber orientation, residual stresses and temperatures predicted by Moldex3D’s analysis into Moldex3D Digimat-RP for an accurate description of the local composite behavior, achieving a precise FEA structural analysis using all the major FEA softwares on the market today.

“With the extensive list of advanced capabilities, Digimat is today the market standard for modeling the thermo-mechanical behavior of reinforced plastics structures taking into account the key effects of injection molding process on the final part performance,” stated Dr Roger A. Assaker, CEO of e-Xstream engineering and Chief Material Strategist of MSC Software.

Providing an integrated framework that streamlines the performing simulation technologies available in the current market is a prevailing trend for the plastic engineering industry, according to CoreTech System.

“On top of the current Moldex3D and FEA integrations, Moldex3D Digimat-RP acts as an enhanced link between injection molding process and FEA structural simulations,” explained Dr Venny Yang, the President of CoreTech System (Moldex3D).

Website: www.adsalecprj.com