BASF has announced the world’s first top mount with polyurethane (PU) bearing and polyamide (PA) housing for the automotive industry.

This Noise, Vibration Harshness (NVH) solution combines the company’s micro-cellular polyurethane elastomer Cellasto and the highly glass fiber reinforced PA Ultramid A3WG10 CR.

The top mount with the Cellasto element and the Ultramid housing is reportedly 25% lighter than conventional aluminum die-cast versions with rubber.

The top mount, developed and optimized for serial production using BASF’s simulation tool Ultrasim, is offered as a complete solution for automakers.

“By joining our PU elastomer Cellasto with an Ultramid housing in a top mount for the first time, we are combining our Verbund expertise in the best materials, customized design and meticulous quality management to provide our customers with rapid component development and implementation, shorter process chains and global use,” stated Wolfgang Micklitz, Head of the global business management Cellasto.

The top mount links the shock absorber to the chassis and thus has a decisive influence on driving comfort and dynamics. BASF noted that Cellasto shows good static and dynamic behavior, has a long life usage and takes up only a small amount of installation space.

Meanwhile, the PA 66 grade Ultramid A3WG10 CR is reinforced with 50% glass fibers and is exceptionally rigid and solid, even at high temperatures. The engineering plastic is particularly suitable for dynamic loads and thus generally a good alternative to metal.

Combined to form the top mount, the actual bearing, the jounce bumper and the dust tube for the shock absorber can be functionally integrated and achieve good damping and acoustics, according to the company.

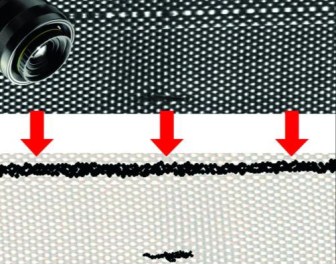

With a manufacturing technique especially developed by BASF, housing and bearing are joined to each other permanently. The CAE tool Ultrasim was used to calculate the load situations relevant for top mounts, the lifespan and the injection molding process, taking into account the reaction forces of the Cellasto core.

Website: www.adsalecprj.com