Isra Vision won the C2 American Innovation Award with its Missing-Feature-Detection (MFD) and Pattern Suppression technologies, the German optical inspection system supplier announced recently.

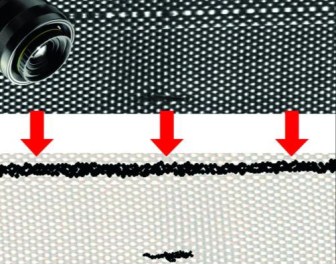

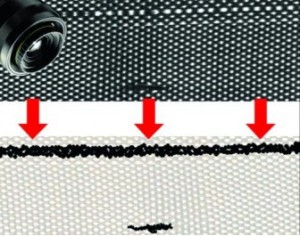

The MFD method allows the inspection of textured material and identifies the missing structural elements distinctively. Irregularities or changes in the structure are detected reliably with the 2D image information. As such, the range of applications for inspection systems also includes functional properties.

Another method for the inspection of textured material serves to suppress structures. Pattern Suppression, with its advanced algorithms, has the ability to recognize light and dark defect points. The structured stripes are suppressed and no longer disrupt as pseudo defects. As an additional feature, the high-speed band measurement simultaneously provides the ability to measure and statistically analyze the distances between the strips in a special channel width.

Typically, line camera inspection systems work with an upper and lower limit value for the intensity values of each line. As soon as the values are outside of the normal range, a defect will be the result. Defect classification is based exclusively on this “threshold value information”.

Until now, conventional systems could handle such volumes of data (which are extremely high in the converting industry) only with simple algorithms. According to Isra Vision, its systems are able to handle more information compared to conventional systems due to the high computing power. This enables the accurate evaluation and generation of detailed information by using 2D images.

The C2 American Innovation Award is organized by C2 Coating & Converting magazine, covering products, processes and technologies from the areas of processing paper, film and foil.

Source: http://www.adsalecprj.com/Publicity/MarketNews/lang-eng/article-67005521/Article.aspx