When one thinks of CNC machines, one often envisions them slicing through steel, turning wood, engraving metal sheets, etc. But have you ever thought of using this humble milling machine for cutting plastic and foam packaging? Probably not!

Given the versatile nature of CNC machines, it shouldn’t come as a surprise that it finds great use in cutting packaging material. It can be seen as the life and blood of the transport and logistics sector as they ensure the safe and secure delivery of goods. If you are just starting out on the journey of CNC cutting for plastic and foam packaging, then you have come to the right spot. Here’s everything you need to know!

What Makes CNC Machine the Right Fit for Cutting Plastic and Foam Packaging?

As mentioned previously, milling machines may not be the first consideration while cutting plastic and foam packaging. However, it makes for an excellent choice given the following benefits:

Greater Production Capacity

While the active role of packaging material is vital during operation in the supply chain, it eventually counts as waste once it has served its purpose. Businesses are never really keen on spending big on the packaging. Against this background, CNC machines offer the convenience of high production and lower per-unit cost, which makes it the perfect solution. At the same time, CNC machines can operate autonomously and can run 24/7, which further boosts the production capacity.

Higher Precision and Accuracy

While businesses may desire cheaper packaging material, it should not be at the cost of quality. After all, foam inserts that are small in size or product cavities that are too big will only be wasteful as they will fall short of achieving their objective. Not to mention that it will also cause wastage of raw material. In this aspect, milling machines manage to deliver once again as they can maintain high precision and accuracy through the power of digitization and automation. They can adhere to tight tolerances and bypass any manual errors.

Easier to Prototype

What we have discussed so far is a condition when you already know about the design, size, features, and specifications of the packaging. However, if you are starting from scratch, then milling machines could play the leading role in infusing efficiency in design. Besides creating prototypes with minimum downtime, CNC machines operate on codes, which will only require minor tweaks once you have worked out the basics. And in case you have manufactured your product using a CNC machine, all you need to do is inverse the code to get a mirror copy that will work as the perfect packaging material!

Lighter on the Pocket

As discussed briefly above, CNC machines deliver cost-effective packaging by offering long-term value. While you will have to invest a significant amount of capital in purchasing the milling machine (if you don’t have one), programming the CAD/CAM software, setting up the machine, and maintaining it, it will all be spread out in the long run as you continue to produce more and more packaging. Plus, CNC machines are already known to be financially feasible due to their characteristics of accuracy, precision, reliability, repeatability, and high-volume production.

Tips for Cutting Plastic and Foam Packaging Using CNC Machine

Now that you know that the CNC machine is the right choice for cutting plastic and foam packaging, here’s a look at some tips to bear in mind while carrying out production:

- Most multi-purpose CNC machines can cut through a variety of plastics and foam.

- Match the tool bit capacity with the material that you are cutting. Tool incompatibility could give rise to unclean cuts and burrs in items like insets and casings, rendering them useless.

- Plastics are typically used in external packaging. As such, you may cut them into pallets and create cubes or blocks to build universal shapes. In doing so, you would effectively make your packaging material (plastic pallets in this case) reusable, which will maximize its worth and value while also contributing to sustainability.

- Use corrugated plastic while cutting plastic containers for specific applications as these are more flexible and durable and will be more capable of accommodating various shapes and sizes.

- Use high-impact plastic as the raw material for crafting the packaging of fragile items. And to cut through this material, use a 5-axis CNC for higher efficiency.

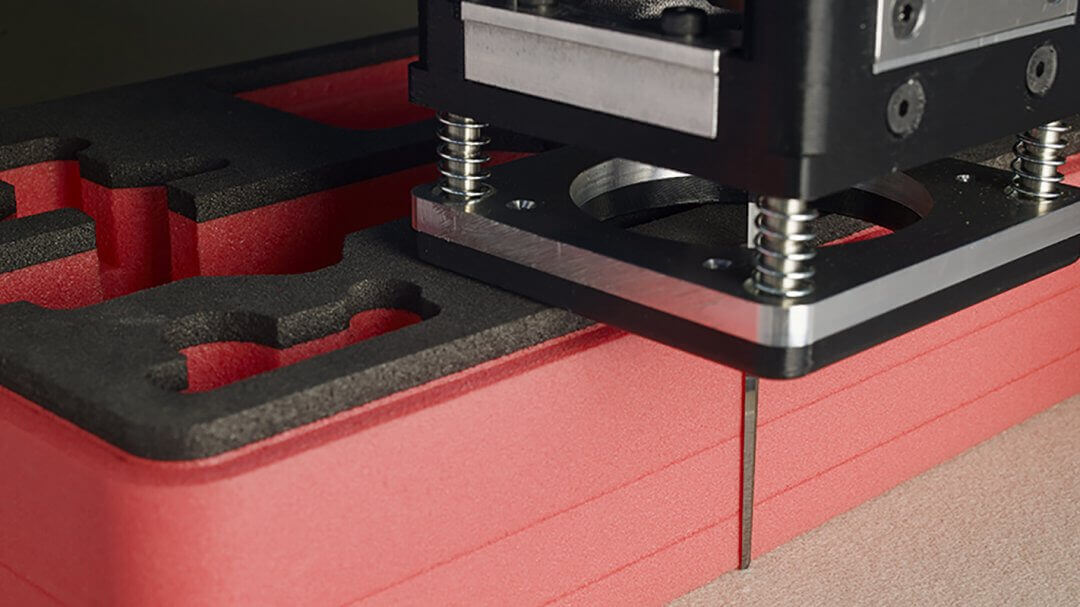

- For cutting foam, use a combination of quick-release spindle or collet and tangential or oscillating knife.

- Use a blower or a vacuum pump to secure light materials.

Final Thoughts

From the above, it is clear that CNC machines can seamlessly cut highly detailed packaging that can secure your goods. At the same time, they maintain cost-effectiveness, accuracy, and precision, which adds to the machine’s value. The reliability of output becomes all the more crucial when you plan on using and reusing the packaging material several times. As such, any investment in a CNC machine for cutting plastic and foam packaging is truly justified!