At Fakuma 2021 in Friedrichshafen, Tosaf /Afula, Israel, and its German subsidiary Tosaf Color Service, Karlstein, will highlight sustainability geared solutions in their wide range of functional, colour and combi-masterbatches for extrusion and injection moulding. These will include colour masterbatches for recyclates with a special focus on post-consumer plastics as well as biodegradable masterbatches. Another focus will be on e-mobility and electronics applications. Here, RAL 2003 Orange and a wide range of UL-listed colours make Tosaf a globally leading producer of masterbatches for the electronics and automotive industries. A third key issue will be light diffuser solutions for polymethyl methacrylate (PMMA) and polycarbonate (PC), including coloured grades. These fully harmonise the appearance of covers for light sources with the colour of the surrounding frame or car body colour, making them virtually invisible until illuminated.

Consistant colouring of recyclates

Due to source-related inconsistencies, recyclates from post-consumer scrap can show significant differences in their basic colour. Tosaf has developed highly efficient masterbatches, specially tailored to cover such variations in a way that the final products meet the customers’ specifications within tight tolerances.

Supporting biodegradability

Biodegradable polymers can provide sustainable alternatives to conventional grades, and this is particularly true for agricultural films. Typically, such films are manufactured with additives to provide specific functionalities ranging from UV stability to antifog and IR filtering effects. Tosaf has developed appropriate additive masterbatches based on biodegradable carriers such as polylactic acid (PLA) and resin (rosin).

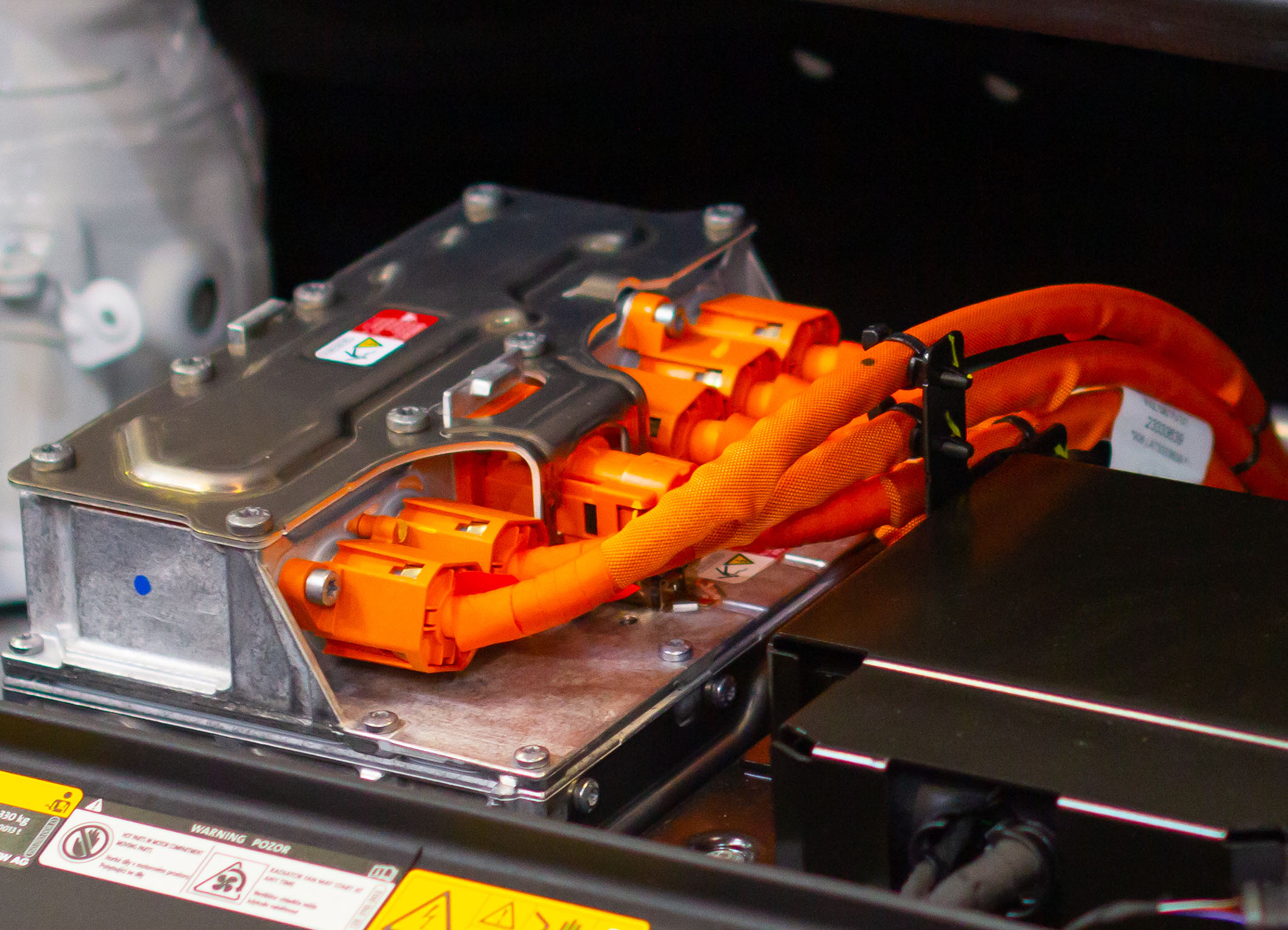

Colours for electronics and e-mobility

Going beyond traditional E&E applications, e-mobility defines new and demanding requirements. One of these is the need for polymers that maintain their orange warning colour virtually unchanged throughout the life of a vehicle. Tosaf has set a worldwide benchmark with such a colour masterbatch according to RAL 2003 for polyamides (PA6 and PA66), polypropylene (PP) and polybutylene terephthalate (PBT). The PA masterbatches were successfully tested at 130° C for 1000 hours without darkening. All grades are available with or without a laser marking additive for identification purposes.

Diffusing light sources

Punctual LED light sources are widely used to illuminate large outdoor advertising boards, car parks and outdoor roads, as well as small control panels in car interiors. This creates a growing need for translucent decorative covers with light scattering properties for a uniformly backlit surface. Tosaf has developed special light-diffusing (LD) masterbatches, especially for polymethyl methacrylate (PMMA) and polycarbonate (PC). In addition to colour-neutral grades, combinations with specific colourings and other functional properties such as UV stabilisers are also available.

For over three decades, Tosaf has been developing and manufacturing high quality additives, compounds and color masterbatches for the plastics industry. With the aim of providing for its customers’ every need, it has continuously grown and developed its offering, production capacity, and global reach, becoming a truly close to the market, global organization.

Servicing customers in over 50 countries in Europe, North America, South America, Asia and the Middle East, Tosaf has over 1000 employees spread throughout its production sites, warehouses, sales and distribution offices around the world.

Tosaf CEO Amos Megides established the company in Israel in 1986, and still stands at its head, leading and inspiring his team to always uphold the following three pillars: Exceptional service, the highest quality and continuous innovation.

Tosaf’s major shareholders include: Megides Holdings Ltd. and the Ravago Group.

For further information about Tosaf please contact:

Ms. Ronit Segal Hayoon

Global Marketing Communication Manager

Tosaf Compounds Ltd.

Phone: +972 9 8984790

Email: [email protected]

Editorial contact, and please send

voucher copies to:

Dr.-Ing. Jörg Wolters

KONSENS PR GmbH & Co. KG

Im Kühlen Grund 10

D-64823 Groß-Umstadt,

Phone: +49 6078 9363-13

Email: [email protected]