Thermoplay, an Italian hot runner system developer for injection molding, has developed a new hot runner manifold that makes the latest innovations in hot half design available

to the injection blow molding sector. The new design will be introduced at K2010, the world’s No.1 plastics and rubber trade fair to be held next Wednesday in Düsseldorf, Germany.

In the most common applications the injection system is made up of an unbalanced manifold with the nozzles threaded on it. The nozzles are often free flow and they are heated by the heat transferred by conduction from the manifold.

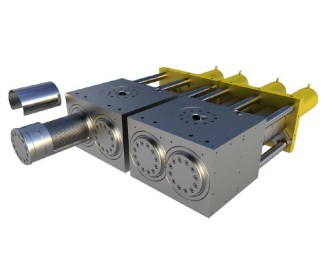

The new Thermoplay design is made up of a manifold with balanced flow channels and the nozzles are assembled to it only by mechanical compression (seated nozzles). This technology allows the nozzles to be always centered within the cavity, reducing the wear in the coupling zone. The nozzle plate is conditioned to have the same temperature as the mold (30°C).

An outer body is screwed externally on each nozzle (so that it can be easily removed) which couples with the forming cavity.

All the Thermoplay nozzles are provided with plastic sealing zones in order to avoid any plastics leakage and to guarantee a high quality injection point on the preform.

Source : www.adsalecprj.com