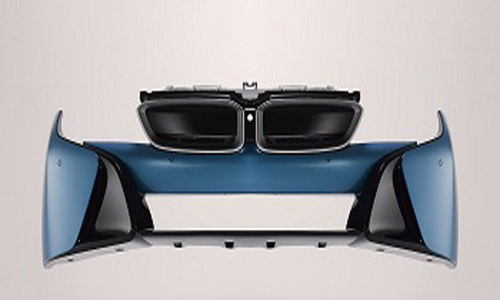

The strategic design of our new generation of products was created by Spirit Design, thus supporting with this innovative and modernized design the changeprocess in our company.

This new and clean layout communicates clearly the strength of High Tech Extrusion: efficiency, reliability and highest technical standards. Due to the puristic shape the new OMNIA extrusion series sets itself significantly apart from competition.

Spirit Design became famous by designing the new ÖBB Railjets (Austrian National Railway trains), for the creation of the private Westbahn (Austrian private railway) and for the development of the whole corporate design of the Vienna’s City Airport Train (CAT). Austrias most innovative industry designer is a think tank for smooth mobility. Apart from trains they create anything that can be driven: fire engines, coaches, lorries, sailing boats, ferries, e-bikes, e-cars, utility vehicles and tractors.

The airport fire engine “Panther” of Rosenbauer (a company in Leonding, Austria) is the most successful fire truck worldwide. Morever the favourite project of Daniel Huber (Managing Director Spirit Design) is a tractor named “Ox”. The rebirth of a cheap tractor, easy to handle and which can be self-assembled. Its bio gas cylinders are removable and can be used for cooking too. This tractor should help farmers in emerging countries to replace their oxen. Our best wishes for Daniel Huber and his team at Spirit Design hoping that the tractor “Ox” becomes reality.

The strengths of OMNIA extrusion lines: Efficiency, Reliability and highest technical standards

OMNIA extruder:

Energy savings because of

– improved efficieny factor of the gear box

– optimized performance of fans

– isolated heater bands and heating-/cooling combinations

– due to isolated adapters instead of cooling flanges between feeder and barrel: no water consumption, no generation of condensation water and simplest maintenace/cleaning

– flexible arrangement of electrical cabinet: electrical cabinet dust-free due to closed air circulation, cooling of electrical cabinet with heat exchanger

– fully encasement of machine, therefore no infiltration of PVC dust inside the machine hence simplest maintenance/cleaning

– convenient emptying of vacuum tank

Theysohn Extruder Control System TEC 4s

– developed with Siemens

– 19” touchscreen, large soft-keys, intuitve colour- and graphic design

– Core is a powerful, fanless and maintenance free industrial-PC

– Communication between TEC 4s and all drives and downstream through Profibus

– Analysis program and remote maintenance via LAN and/or WAN

– In 99% of all cases customers can maintain or exchange spare parts themselves (CF-card, frequency converters, software update, ..)

– Pre-leading quality measurement: in-time visualization if actual values of resulting figures are not correct

– Diagnostics- and drives information: Easy diagnosis of the extrusion line

– Maintenance management: Display of an alarm when reaching the maintenance interval

– Automatic self-tuning of temperatures: self-tuning at any switch-on of heating (helpful when often changing tools)

– Heating current monitoring (quick detection of damaged heating zones)

– Timer heating (heating-up of extruder without operator on site)

– Speed controll of vacuum- and water pumps (vacuumproduction in line with demand) incl. digital display of vacuum

– Production data acquisition (Monitoring, storage, evaluation)

– All process parameters of the extruder incl. vacuum level of calibration table and other, can be stored and administrated on the TEC 4s

OMNIA calibration table

Energy savings because of

– usage of frequency controlled vacuum- and waterpumps

– up to 80 % energy savings in comparison to conventional calibration tables

– vacuum production in line with demand

– demonstration of energy savings at customers site with test systems possible

Further advantages:

– optimized geometry of water collection pan thus avoiding flooding of the whole pan

– angular position of tank for easier cleaning

– 2 Plexiglas frontwindows with foamed gaskets (opening without tools possible, sealed by closing without use of silicone)

– Optional: water deduction directly into drainage system (avoiding of water contamination)

The High Tech OMNIA extrusion line is already in use at several customers, who expressed all their excitement about the possibilities of savings, the new design and the advantages, particularly in cleaning and maintenance.

High Tech Extrusion

High Tech Extrusion is the umbrella brand name for the four extrusion specialists Theysohn, Technoplast, Topf and Extruder-Komponenten Salzgitter. High Tech Extrusion operates internationally with four production sites in Austria and Germany as well as sales offices in Russia and India. This group of companies, which bundles 30 years of experience in extrusion technology, belongs to HTI, High Tech Industries AG, an international technology group offering high-tech products in the fields of lightweight construction, engineering and energy technology. Renowned companies such as HTP, Gruber & Kaja, BBG Baugeräte and Hitzinger are part of the HTI Group.