Together with its partners—metal transformation and coatings solutions provider Bekaert (Kortrijk, Belgium) and automotive plastic composite processor voestalpine Plastics Solutions (Bunschoten, The Netherlands)—materials supplier BASF (Ludwigshafen, Germany) is currently working on the development of thermoplastic components that are reinforced with steel cord fabrics and fabricated by means of injection molding.

The three companies have joined together with the objective of employing and further developing this new EASI (for Energy Absorption, Safety and Integrity) technology with partners in the automotive industry. In contrast to other types of reinforcements like continuous fiber-reinforced laminates or other carbon or glass fiber fabrics, the steel cord inserts especially ensure the integrity of the molded part’s function in a crash situation. This reportedly creates an entirely new performance class.

Bekaert, voestalpine Plastics Solutions, and BASF have been investigating steel cord-reinforced injection molded parts since 2010. The first production part using the predecessor technology was based on compression molding with GMT (glass mat-reinforced thermoplastics), and received the AVK Innovation Award in 2008. Working together, the three companies are now focusing on conventional injection molding of parts with steel cord reinforcement.

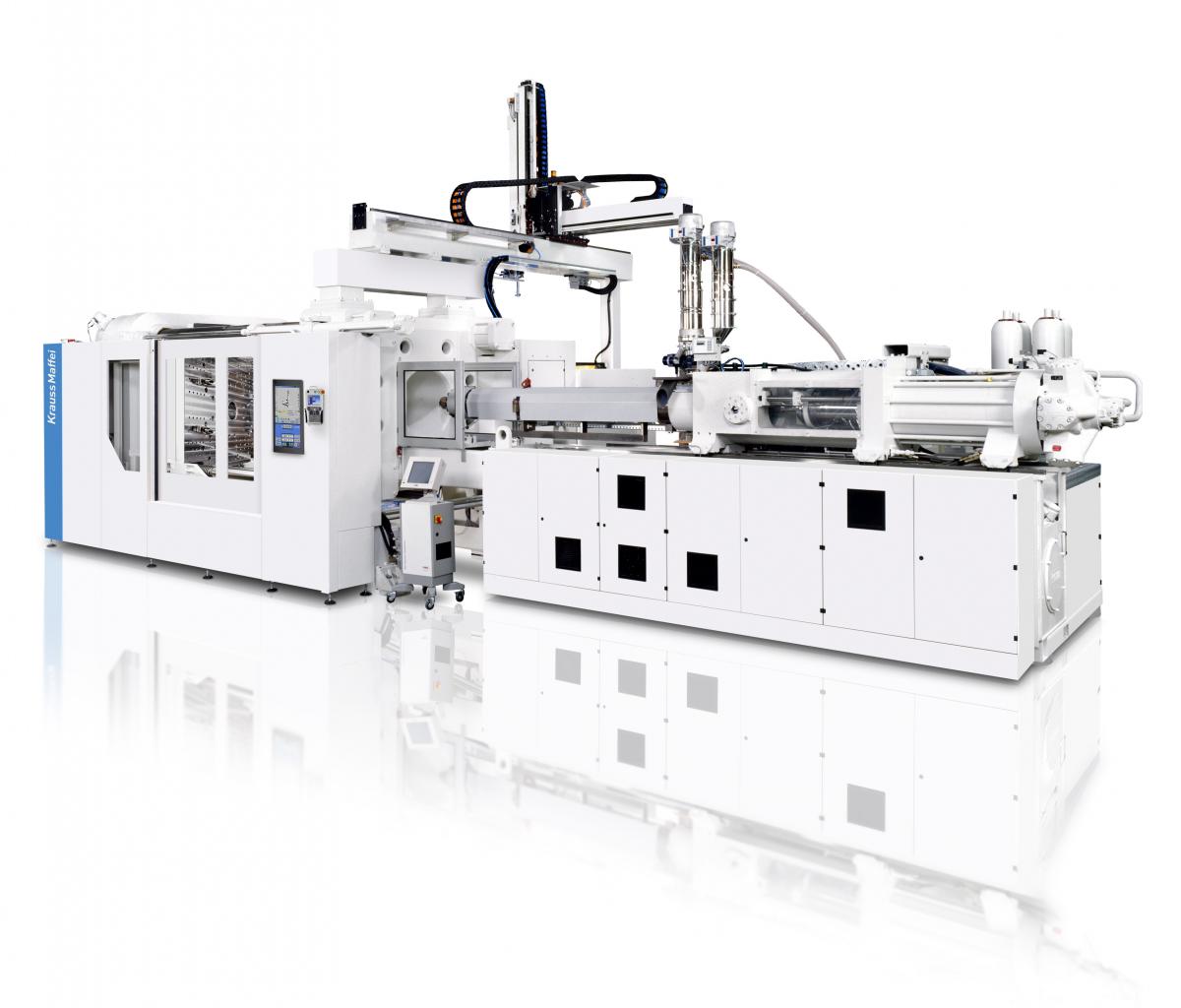

Bekaert contributes its expertise in the manufacture of steel cord fabrics to the partnership, while voestalpine Plastics Solutions is responsible for the processing technology and part production using injection molding. BASF, for its part, is continuing to develop its crash-optimized short- and long fiber-reinforced polyamide resins in the Ultramid product line for use in combination with the steel cord inserts.

At the same time, the company is expanding its expertise in the prediction of part performance by enhancing the capabilities of its Ultrasim simulation tool through incorporation of representation methods and material models for the new composite materials. By using polyamide as a matrix material it is not only possible to apply the EASI composite technology attached or semi-structural parts but also gain entry to components of the body-in-white (BIW), which need to run through the 150-200ºC e-coating process.

The steel cord reinforcement employed in the EASI concept ensures that an injection molded part retains its structural integrity. Thus, while EASI parts may be damaged in a crash, they are still able to absorb energy and lead it further into the structure. This is a decisive innovation when compared to molded plastic parts with conventional reinforcement that usually fracture upon failure. The material is thus predestined for regions that are intended for absorption and harmonic distribution of crash energy.

A video of the crash impact performance of the composite can be found here. The resultant level of performance cannot be attained with other types of reinforcing technology. Vehicle components where these characteristics can be exploited include structure-relevant attachments such as bumper beam carriers or front ends as well as BIW components. The three partners believe that combining polyamide injection molding and steel cord reinforcement provides optimal access, specifically to parts that must retain their supporting function and structural integrity in order to further distribute forces in a [email protected]

Source : www.plasticstoday.com