Since the beginning of this year, Brett Martin Ltd., based in Newtownabbey, Northern Ireland, has been operating the most powerful counter-rotating twin screw extruder manu-factured so far by battenfeld-cincinnati, Bad Oeynhausen/ Vienna. With this high-performance extruder for PVC sheet production with an output of up to 2,000 kg/hr, Brett Martin Ltd has significantly expanded its production capacity.

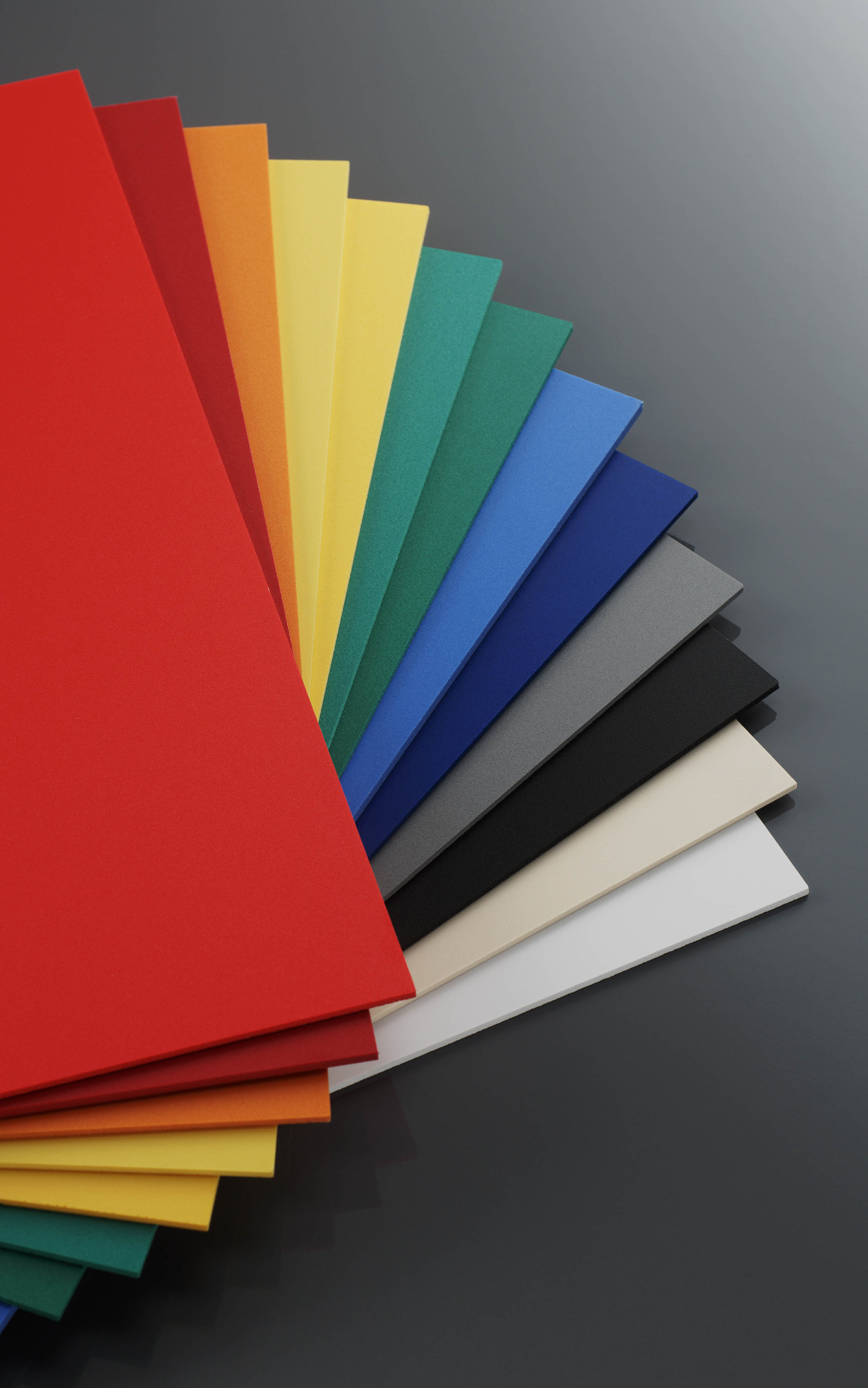

Brett Martin Ltd makes high-quality specialty plastic products for the building construction, manufacturing, printing, roofing and display industries. In the area of sheet production from PVC, PMMA or PC, Brett Martin Ltd is known as a global leader offering a great variety of customized products ranging from light domes for the Wembley Stadium and protective shields to typhoon-resistant McDonald’s signs.

In its production plant, Brett Martin Ltd already operates several extruders from battenfeld-cincinnati and is very satisfied with their performance. Therefore the plastics processor also chose an extru-sion line from the Austrian-German machine manufacturer when investing in high-performance equipment. “We were particularly impressed by the outstanding flexibility of this extruder, which enables us to produce PVC sheet with a wide range of thicknesses from 3.0 to 25 mm”, Technical Director at Brett Martin Ltd, David Robinson, explains. In addition to its wide processing window, this currently largest counter-rotating extruder in the battenfeld-cincinnati portfolio offers the benefits of high output, robust design and easy operation.

With its closed-loop, self-regulating Intracool® screw tempering system and its efficient apc® (air power cooling) barrel cooling system, the extruder ensures constant melt temperatures and thus high standards in product quality.

About battenfeld-cincinnati:

The battenfeld-cincinnati group with production facilities in Bad Oeynhausen and Kempen (Germany), Vienna (Austria), Shunde (China) and McPherson (USA) ranks among the leading manufac-turers of energy-efficient, high-performance extruders and com-plete extrusion lines according to customers’ specifications. The company is organized in three product-oriented Divisions across all manufacturing sites: Infrastructure (pipes), Construction (PVC and WPC profiles, PVC sheet) and Packaging (non-PVC sheet, granula-tion, calendering and lamination equipment). battenfeld-cincinnati’s customers benefit from the group’s extensive global sales and service network.