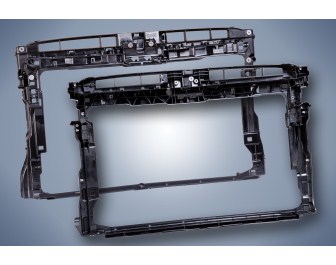

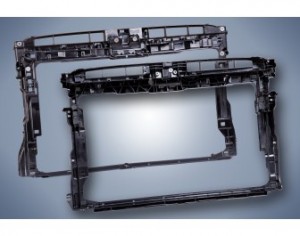

The front end carrier in the new Volkswagen Golf 7 is now entirely made of plastics, as BASF’s Ultramid B3WG8 highly reinforced polyamide (PA) and its simulation tool Ultrasim help in eliminating the sheet steel parts that had been attached previously.

In addition to limited space for installation, the requirements to the all-plastic part include a variety of challenging load cases according to BASF, among them, static and dynamic hood latch failure, where incorrect opening and closing of the engine’s hood was simulated and tested under harsh conditions. At the same time, the stiffness and vibration behavior of the system comprising front end and radiator was optimized on the basis of CAE analyses and validated in an actual vibration test.

Special attention was devoted to the crash sensors attached to the front end. They ensure deployment of the airbag at the right moment in the event of a head-on collision. For this, the plastic part must exhibit a certain dynamic stiffness at a defined location and satisfy the automaker’s crash acceleration requirements, explains the chemical company. In a real-world test, the vibration response of the part corresponded to what was designed and predicted by Ultrasim. The primary load cases provide the basis for a front end design; from these, an optimized topology can be derived.

This topology gives the designer valuable information regarding the final shape of the part. Only slight modifications were needed in moving from the prototype of the front end carrier to its serial production because of the accurate predictions of Ultrasim.

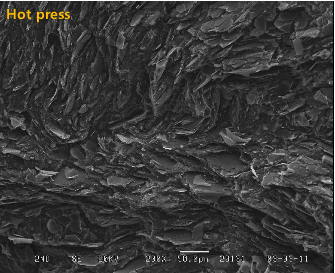

Furthermore, BASF says Ultrasim, together with its special failure models, can be integrated into the calculation environment for the automaker’s entire vehicle. This requires, however, that very specific, e.g. crash-relevant material data for the plastic, be available which describe exactly the effect of temperature, moisture and rate of load application. A simulation is thus preceded by acquisition of extensive material data from experiments conducted with the aid of complex testing and measuring instruments. The simulation tool is then able to predict failure behavior, strain rate dependence, and even tension-compression asymmetry as a function of fiber orientation.