A conductive long carbon fiber thermoplastic (LCFT) compound developed by Honam Petrochemical (Seoul, Korea) and based on polypropylene (PP) has been employed in the bipolar plate of a fuel cell.

Through this development, the company hopes to reduce the overall cost of fuel cells, 40% of the cost of which currently comprises the bipolar plates that are normally fabricated from metal plates or carbon fiber/epoxy composites.

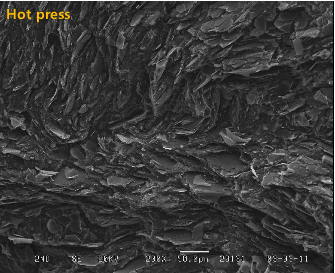

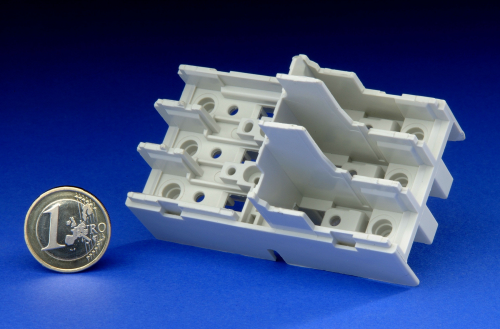

Honam prepares the LCFT using a twin-screw extruder and the pellets measure 8-12 mm in length and container a 50% carbon fiber loading. These pellets are then blended with more PP resin and graphite powder, and molded into plates using a hot press molding process employing 10,000 psi of pressure. The bipolar plates measure 2-3 mm in thickness and 100 x 100 mm square.

A bipolar plate comprising 15% LCFT:5% PP resin:80% graphite powder boasts a conductivity to 123 S/m, which meets US Department of Energy (DOE) requirements of 100 S/cm conductivity, and a flexural of 40 MPa according to Sungrok Ko, senior research engineer at Honam. A formulation of 5% LCFT, 30% PP and 65% graphite powder exhibits a flexural strength of 30 MPa and conductivity of 45 S/m.

The worldwide market for fuel cells was valued at an estimated $800 million in 2011 according to Ko, who anticipates that the market structure will shift from a portable fuel cell-centric market in 2012 to one more reliant on the automotive sector in 2015.

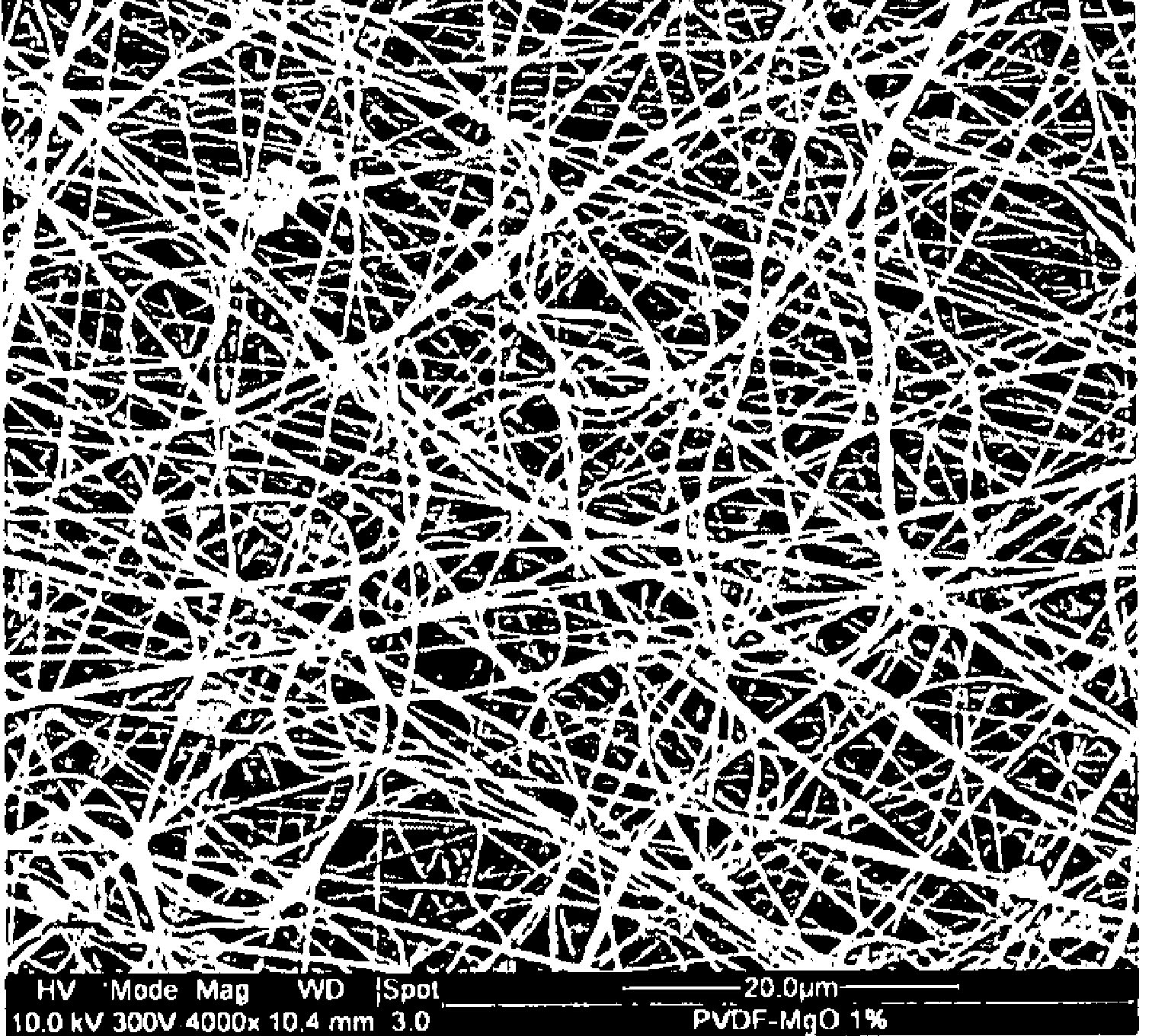

Previous attempts have been made to injection-mold bipolar plates from PPS resin, which was considered better equipped to cope with the temperature requirements of fuel [email protected]