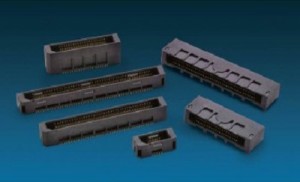

According to Ticona, the engineering polymers business of Celanese Corporation, Zenite is the only liquid crystal polymer (LCP) to deliver the required ultra-flatness for the Tiger Eye Series TEM terminal strip from Samtec Inc, a worldwide manufacturer of electronic interconnects.

Lead-free solderable, high flow and low warpage, Zenite ZE55201 is part of the Vectra/Zenite family of halogen free, high performance polymers from Ticona. It has high temperature resistance, allowing lead-free soldering and applications requiring a heat deflection temperature (HDT) of up to 270°C.

“The only LCP material we’ve found to meet our flatness specifications for the Tiger Eye Series TEM is Zenite ZE55201 from Ticona,” said Doug McCartin, HUB Engineering Manager at Samtec. “Our molder, Plastikos Inc, tried every possible LCP but each resulted in a bow issue due to the part geometry variations.”

Samtec chose the 50% mineral/glass fiber reinforced Zenite ZE55201 for this TEM terminal strip because it is suited for low-profile connectors, which require better balanced shrinkage to avoid warpage and is designed for applications requiring ultra-flatness. The material is UL 94 V-0 listed at 0.8mm thickness in black.

“No other LCP in the industry delivers a combination of flatness and flowability, which is critical for complex parts with very stringent specifications, especially those found in thin wall connectors,” said Ruth Castillo, Vectra and Zenite LCP global Business Director, Ticona.

The Tiger Eye TEM is an industry standard, according to Ticona. It meets the need for reliable micro-pitch, rugged interconnects thanks to the right combination of high performance engineering thermoplastics and base metals, along with pin design, geometry and assembly process.

The TEM terminal strip uses Zenite ZE55201 injected molded insulators that precisely hold the contacts in place. These contacts are used in a variety of applications, including industrial automation, process control, miniature/handheld devices, diagnostic equipment, communications, energy, security and surveillance.

Source: http://www.adsalecprj.com/Publicity/MarketNews/lang-eng/article-67006541/Article.aspx