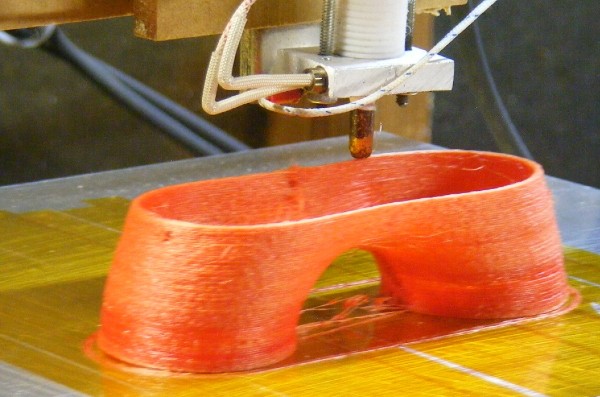

Next Generation Recyclingmaschinen GmbH (NGR) brought to CHINAPLAS 2015 the new P:REACT polyethylene terephthalate (PET) recycling equipment, which made its world premiere only as recently as NPE in March.

The P:REACT follows the design principles of Liquid State Polycondensation (LSP), utilizing the inherent capability of PET to post condensate in the molten phase under vacuum, which leads to an increased intrinsic viscosity (IV).

“It allows us to process PET scrap, increasing the IV from for example, 0.6 IV value to 0.75 or 0.8 in a very short time, say 20-30 minutes,” explained Josef Hochreiter, NGR’s CEO. “This new technology put us in a very good position in the market.”

According to NGR, this high performance vacuum effectively decontaminates the material from harmful chemicals – securing further use of the material for 100% food contact.

“We can now offer a full spectrum of recycling equipment, from post-industrial, post-consumer through to PET recycling,” emphasized Mr Hochreiter. “Together with our Customer Care Center in Taicang, we are ready for many different interesting applications in China.”

He said that PET films and fiber recycling is a very fast growing segment in Asia, offering huge potential for the company.

NGR expects the financial year 2014-2015 will pose a growth rate of around 10%. The company more or less put is focus in Europe and the US in the last few years, according to Mr Hochreiter, but now intends to intensity activities in China following the establishment of the Customer Care Center last year.

“We have done a lot of trials already in Taicang and feel a very high acceptance from the Chinese market,” he said, adding that the pursuit of green manufacturing by the Chinese government will spur the development of recycling sector.

Website: www.adsalecprj.com