Metravib, a dynamic mechanical analysis specialist, introduces a brand new Dynamic Testing Machine series, designed and dimensioned to offer a wide range of dynamic tests in one single test machine:

# Glass transition

# Frequency sweep

# Payne & Mullins effect

# High frequency testing

# Fatigue testing under various controlled waveforms

# Crack growth analysis

The test can be accommodated with the materials due to a large choice of innovative specimen holders that give practical and efficient testing solutions matching to most of solid materials: elastomers, polymers, composites, metals and ceramics, etc…

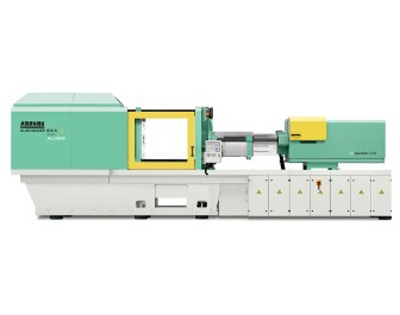

The new DMA+ series design consists of a floor standing mechanical test frame, controlled by a computer station equipped with a dedicated software MULTITEST.

Each DMA+ models includes a thermal chamber designed for an operating temperature range from -150°C to 500°C that can be associated to various cooling solutions: cryogenic source, air chiller…

The test can be carried out by setting specific gas conditioning: neutral gas, oxygen rate control, etc.

The principle of the crack growth test consists in initiating a crack on one side of a specimen and following up the growth of the crack using an optical system during a dynamic mechanical fatigue test.

A cutting system is integrated inside the front door of the thermal chamber, and allows initiating the crack, very precisely and repeatedly.

In front of the thermal chamber the motorized binocular microscope makes possible to follow up the crack growth with a unique accuracy.

Source : www.adsalecprj.com