OEM-Approved Apex® 1523-LG Compounds from Teknor Apex Retain PVC Cost Advantage over Elastomers, Are Scratch- and Mar-Resistant, and Facilitate Precise Color Matching

PAWTUCKET, RI, U.S.A., February 15, 2018: A newly developed series of flexible PVC injection molding compounds that have been used successfully in automotive window encapsulation exhibit substantially lower levels of surface gloss, providing a rubberlike finish that matches that of adjacent EPDM components while retaining the cost-performance advantages of PVC. Teknor Apex Company will introduce the enhanced formulations at NPE2018 (Booth S22045).

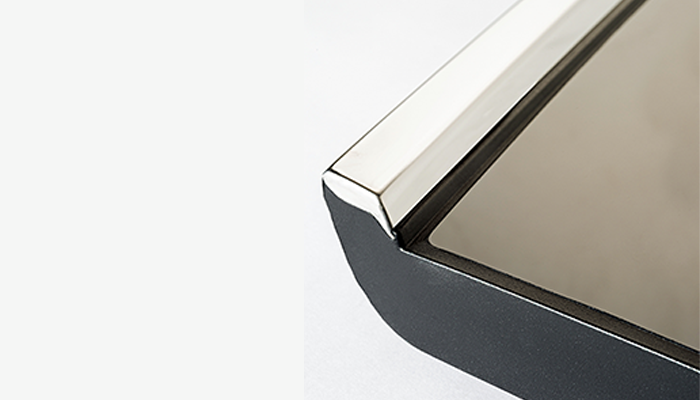

The newly enhanced Apex® 1523 compounds, named the Apex 1523-LG Series, exhibits gloss levels similar to those of EPDM rubber beltline seals or glass run channels, enabling manufacturers of PVC-encapsulated windows to meet OEM demand for a closer match in the surface finish of these critical appearance parts. The lowest gloss levels of standard PVC compounds for window encapsulation are in the 9 to 12 range as defined by SPI gloss finish standards, and they are achieved through etching or sandblasting of the tooling surface. In contrast, Apex 1523-LG Series compounds achieve a gloss level in the 3 to 4 range without need for surface treatment of the tooling. This eliminates the costs associated with the tooling maintenance and repair required to keep a consistent surface appearance from part to part.

Apex 1523-LG Series compounds have received several OEM material approvals, including the GMW-16084 specification for quarter windows from General Motors and the MSDC543 specification for quarter windows and sunroofs from Chrysler. Teknor Apex can manufacture these compounds in the U.S., Europe, and China.

“Our introduction of low-gloss compounds is particularly important since PVC is the dominant material for window encapsulation and is valued by manufacturers for its advantages over elastomers,” said Steve McCormack, industry manager of the Teknor Apex Automotive Group. “Like standard PVC, new Apex 1523-LG Series formulations are relatively low in cost, provide better scratch and mar resistance, excellent bonding to glass, and superior colorability. In fact, Teknor Apex can match to any color and supply uniform product no matter how many places in the world a customer carries on manufacturing.”

###

About Teknor Apex. Teknor Apex Company, a privately held firm founded in 1924, is one of the world’s leading custom compounders of plastics. Teknor Apex produces flexible and rigid vinyl, thermoplastic elastomers, nylons, color master batches, specialty chemicals, and hoses. The company is headquartered in Pawtucket, RI, U.S.A. and operates thirteen manufacturing facilities worldwide in the United States, Belgium, Germany, China, and Singapore. To learn more visit: www.teknorapex.com.

The Vinyl Division of Teknor Apex Company is a leading manufacturer of custom compounds, including ApexÒ flexible and rigid vinyl, FlexalloyÒ vinyl elastomers, FireguardÒ low-flame, low-smoke compounds, and HalguardÒ low-smoke, halogen free, flame retardant compounds and elastomers. The Division is a global supplier to the appliance, automotive, construction, medical device, wire and cable, and other industries.

READER INQUIRY INFORMATION: Address all mail inquiries to Teknor Apex, 505 Central Avenue, Pawtucket, RI 02861 U.S.A. Tel: 1-401-725-8000. Tel. from U.S. only: 1-800-554-9892. Fax: 1-401-729-0166. E-mail:[email protected].

—

Robert J. Martino

Martino Communications Inc.

Tel: 1-203-321-0787

Email: [email protected]