Delivery times shortened significantly

With the introduction of flow assembly and the modernization of the machinery in his factory robots ENGEL respond to the continuously increasing volume of orders in automation technology. A total of EUR 2.3 million injection molding machine manufacturer and automation expert invested in his Austrian Steyr site.

“The automation market is growing worldwide,” said Dr. Stefan Engleder, managing technology and production of ANGELS, to the trade press at Fakuma in October 2012 in Friedrichshafen. Already 50 percent of all heavy machinery and 35 percent of small and medium machine supplies from ENGEL, including automation, with an upward trend. “With the new structure, we now realize even with full order books, short delivery times for ENGEL viper linear robot and integrated system solutions,” said Stefan Engleder. “At the same time we have increased both the production capacity.”

In addition to shorter delivery times result in further benefits to customers. Thus, for much more flexible and more responsive to short-term job changes and customer demands without disturbing the production process elsewhere.

The clock from the incoming goods inspection and commissioning

A special feature of the flow process at ENGEL is that all steps are performed in the assembly cycle. This includes commissioning, avoiding unnecessary delays and the client from the beginning of planning security guarantees. Since the computerized quality control of assemblies and components has been integrated into the production cycle, this also increased the security process.

Two assembly lines for ENGEL viper robots have taken their operations in September. “90 percent of all orders we are able to cover it with the moving assembly line,” says Engleder. “Also, most of the options will be made in time.” ENGEL 2003 had one of the first injection molding machine manufacturer introduced the moving assembly line for the production of small and medium machine at the headquarters Schwertberg. In large machine shop in St. Valentin in April this year, the injection units are produced at the clock. With the recent investment in Dietach now followed the third of the Austrian production sites.

“The moving assembly line at ENGEL the preferred manufacturing concept” emphasizes Stefan Engleder. “We provide the efficiency of our production continuously to the test and invest in the optimization when the market demands. This will strengthen our global competitiveness. “

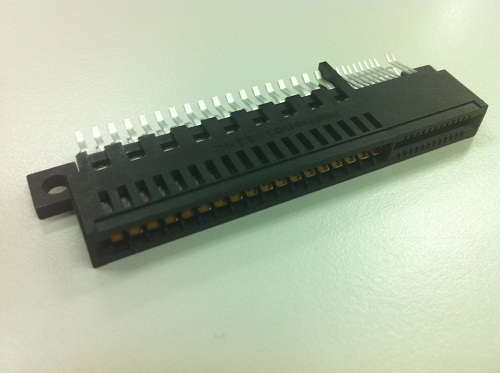

ENGEL viper robots for injection molding machines of all brands

except for simple pick and place applications, see the viper robot increasingly for insert and multi-component processes used. “Several years ago, it still needed special automation solutions,” said Engleder. “We are now able to serve a broad range of applications with standard linear devices.” With seven sizes covering nominal payload capacity of 6 120 kg, can the ENGEL linear robot adapt to the automation task. Here, the robot unite on all sizes across maximum stability with maximum dynamics and comfort for the operator. Thanks to the innovative design using laser-welded steel sections could the weight kept low, and so the load capacity can be increased. Clever software packages reduce the oscillations during long axis dimensions and optimizing the robot’s movements and dynamics.

Integrated in order of increasing complexity of the applications to ensure ease of use of the robot as well as the complete systems, controls the ANGEL – both the viper linear devices as well as the easix Mehrachsroboter – completely in the control of the CC 200 ENGEL injection molding. This outstanding performance and efficiency features ensure that the ENGEL viper robot not only sold in a package with injection molding machines, but increasingly also to replace old equipment and used in injection molding machines of other brands.

Source : http://www.engelglobal.com/