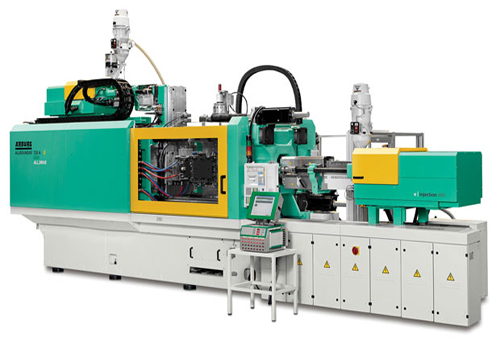

Austrian injection moulding machine manufacturer ENGEL will, for the first time ever, be demonstrating its fully electric,

automated ENGEL e-motion 1340/280 T as an efficient solution for the production of Petri dishes at the Medtec Europe from March 22-24, 2011 in Stuttgart, Germany.

According to ENGEL, this system is said to be yielding 25% more output and 65% less energy consumption – a new standards for Petri dish production as stressed by the manufacturer.

Petri dishes belong to the standard consumables in biochemical laboratories. They are used to cultivate microorganisms and for cell cultures. These applications require great material transparency, a smooth base and high purity. Together with four partners, also all leaders in their fields, ENGEL has developed a complete system solution for the fully automated production and packaging of these demanding laboratory products. The high-performance system had its premiere at the K2010.

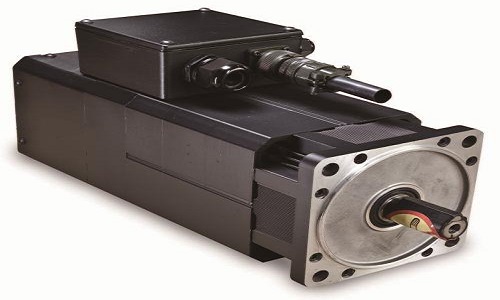

ENGEL e-motion 1340/280 T is for applications in clean rooms with encapsulated drives, sealed joints, smooth surfaces and an encapsulated barrel. Polystyrene is used to create eight covers and eight bases of the Petri dish in a 3.7-second cycle with an 8+8-cavity mold made by Plastisud. Cycle times lie at 4.5 seconds with the usual machine engineering. During a mold open time of 0.6 seconds, the parts are removed fully automatically in pairs, covers and bases are fitted together, finished dishes are stacked and packed into tubular bags.

The complete production area of system is encapsulated as a clean room, including assembly and packaging, thus ensuring 100% product protection. The project partner for the clean room technology is Alpha Ionstatex, while the complex automation, which also comprises integrated quality testing, is provided by Hekuma. Project partner Ineosnova is the polystyrene supplier.

In addition to the short cycle time, the high-performance production cell also scores with a particularly low energy consumption. Thanks to the use of a fully electric injection molding machine, the energy costs compared to production with a normally used hydraulic machine can be reduced by up to 65%. At an energy price of 0.12 euro/kWh, this corresponds to a saving of 30,000 euros per year.

Source : www.adsalecprj.com