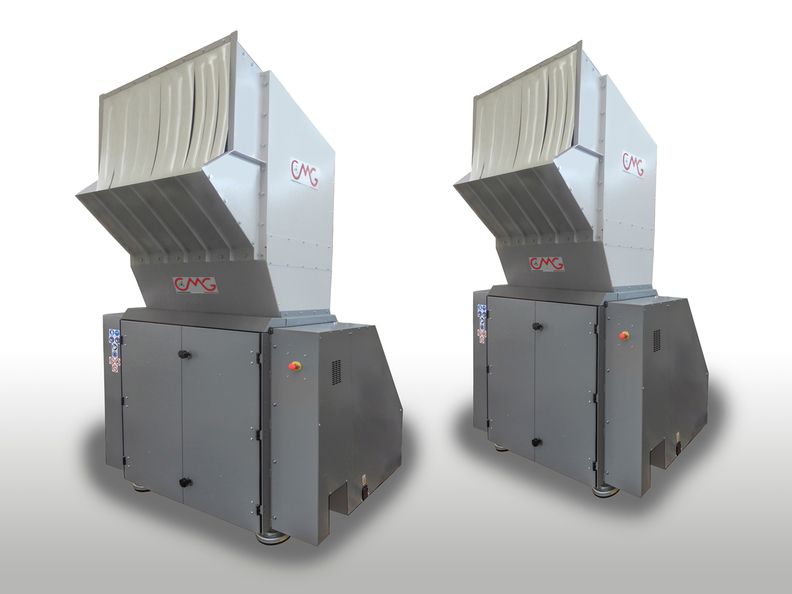

The G55 series includes two models—the G55-90 and G55-120— designed to deliver exceptional capacity, energy efficiency, and cutting-edge precision.

Built for operations requiring throughput between 700 kg/h and 1,300 kg/h, the G55 Line promises maximum productivity, consistent regrind quality, and significant operational savings.

The new series boosts a modular design and adjustable rotating knives, which enable it to handle a wide variety of materials and part geometries. CMG’s proprietary integral sound enclosure and feed hopper design enhance noise reduction and feeding efficiency.

CMG’s full-vacuum regrind conveying system ensures that particles are transported with zero mechanical stress, preventing dust formation and avoiding the air pollution often caused by conventional through-fan systems. This not only preserves regrind quality but also supports a cleaner, safer working environment.

All units are fitted with EISA premium-efficiency motors and can be equipped with Adaptive Motor Power (AMP) controls, allowing for energy consumption as low as 25 Wh/kg—an improvement over conventional granulation systems that often exceed 50 Wh/kg.

Ease of maintenance is another feature of the G55 Line. With full access from both the front and rear of the unit, operators can complete cleaning and routine maintenance in minutes and without tools. The design greatly reduces downtime and simplifies service procedures.

Source: sustainableplastics.com