PolyOne Corporation unveiled a breakthrough series of solutions for natural fibers that expand processing and material options for the composites market. Developed to help increase options for customers, this new portfolio has been formulated for compatibility with many natural fibers as well as post-consumer recycled natural fibers.

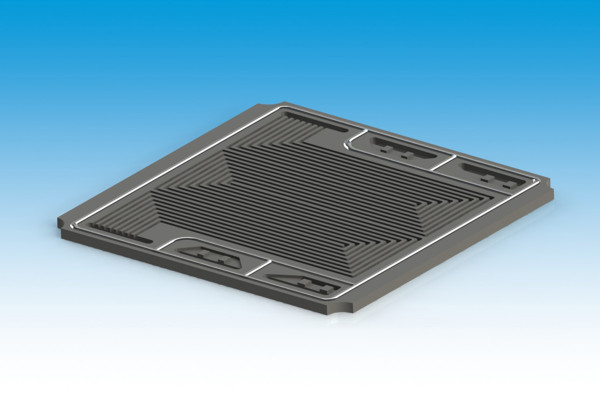

This new patent-pending technology is the latest addition to PolyOne’s line of colorant and additive offerings for wood plastic composite marketplace. OnColor™ WPC colorants and additives include fade-resistant, “cooler-to-the-touch” low heat absorption colorants in highly loaded, small-bead geometry that improve the distribution of color during extrusion and molding operations. In addition, the company also offers a line of “streaker” technology products that mimic the aesthetic appearance of tropical hardwoods in WPC formulations.

Dr. Cecil C. Chappelow, vice president, innovation, sustainability and chief innovation officer, said, “We are confident that this technology portfolio, which can be applied to a broad range of applications, provides an effective path for our customers to achieve their long term sustainability goals. This is another example of PolyOne’s commitment to delivering value-creating solutions that directly reflect the needs and challenges of the marketplace.”

Manufacturers are boosting the amount of natural and post consumer recycled fiber content in plastic composites to help achieve sustainability goals and targets. This trend creates concerns surrounding the performance of the finished parts. To eliminate concerns, Smartbatch™ WPC solutions help to optimize the following performance and appearance factors:

* UV stability

* Mold and mildew resistance

* Dimensional stability

* Resistance to water absorption

* Structural integrity

* Compatibility with the polymer matrix

* Scratch and mar resistance

* Aesthetics

John Van Hulle, general manager, Color and Additives, said, “These landmark additions to the Smartbatch™ WPC family of masterbatch colorants and additives will expand significantly the range of options available to WPC processors and others looking to increase the use of natural fibers and those from post-consumer recycle streams. Further, the new formulations are designed to provide processing improvements for better overall system cost performance.”

About PolyOne

PolyOne Corporation, with 2008 annual revenues of $2.7 billion, is a premier provider of specialized polymer materials, services and solutions. Headquartered outside of Cleveland, Ohio USA, PolyOne has operations around the world.

Source: specialchem4polymers.com