Pallmann Maschinenfabrik GmbH and Co. KG has extended its range of PANTHER recycling granulators with a model that has been specially designed for recycling reusable materials from polyethylene terephthalate (PET) bottles.

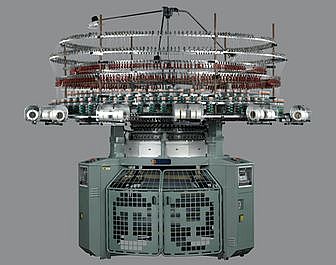

With the Pallmann PANTHER UltraGranulator, individual PET bottles are continuously fed into the cutting chamber, by means of a conveyor belt. Massive, angled rotor knives work with a very close cutting gap against opposing slanted counter knives and cut the bottles into flakes.

The special rotor really does cut diagonally and this keeps energy consumption to a minimum. The lower part of the housing is fitted with a large screen, which holds the PET flakes in the cutting chamber until they are discharged through the screen holes.

The mesh size can be selected, which determines the size of the flakes and throughput rate of the granulator. Throughput rates of up to 3.5 ton per hour are possible with a flake size of approximately 14mm and the appropriate machine size, according to Pallmann.

After being cut, the material is pneumatically suctioned and transported into a cleaning system, in which the PET flakes are separated from the polyethylene (PE), which is still contained in the bottle caps.

Easy access to the cutting chamber makes it easier to clean the PANTHER UltraGranulator and wearing parts can be replaced quickly. It is suitable for continuous operation under tough conditions, the company emphasized.

The heavy duty, compact machine can also be integrated into existing recycling lines or used as a stand-alone machine without any problems.

Every year, about 460 billion PET bottles are currently produced worldwide. In Europe alone, 65 billion or more PET bottles were recycled in 2013.

Website: www.adsalecprj.com