UK-based Aviation Enterprises Ltd. (AEL) has launched its third generation out-of-autoclave carbon/epoxy materials specifically designed for tidal blade spars.

Comparing to its second generation prepreg materials used to date, this third generation materials take advantage of a new high toughness resin that is particularly resistant to moisture ingress.

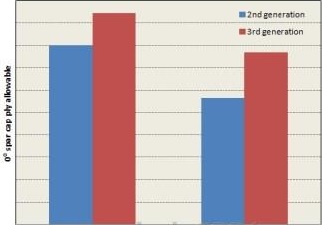

According to AEL, the incorporation of these materials in a special format ensures near-autoclave laminate quality whilst enabling the elimination of interim debulks during layup. Consequent labor savings of approximately 30% are anticipated during lamination, and typical design allowable gains of 18% (tension) and 36% (compression) are achievable due to the optimization of ply thickness and careful focus on critical laminate details.

The new materials are supported by comprehensive accredited test data, covering fatigue performance and the effects of seawater immersion in addition to more routine information, said AEL.

This development is the latest result of AEL’s ongoing tidal blade development program which has involved significant collaborations with suppliers and universities, and has been assisted by the Carbon Trust and the Technology Strategies Board.

Source: http://www.adsalecprj.com/Publicity/MarketNews/lang-eng/article-67010504/NewsArticle.aspx