Filtering and conveying of plastics melt as well as innovative valve technology are the speciality of the Muenster-based KREYENBORG GmbH. During this year’s Interplastica particularly efficient systems will be brought into focus. Furthermore components for underwater pelletizing systems will be presented by BKG Bruckmann & Kreyenborg Granuliertechnik GmbH.

Interesting for Polymer producers is the increasing trend to replace large area filters in Polymer lines by screen changers. This results in a number of advantages, like e. g. the quick change of the filter media or the short residence time of the material in the screen changer. Altogether the profitability of the complex line is considerably increased by screen changers. The special filters of the type POLY are available for throughputs of up to 45.000 kg/h, depending on material and viscosity. Already in 2008 KREYENBORG successfully supplied three of such mega systems for PET production.

The KREYENBORG V-type screen changer with power backflush technology provides for an especially profitable filtration. Integrated into very sensitive extrusion applications it permits the production of most high quality products out of very polluted input material. Its inimitable backflush system thereby ensures a very high screen lifetime and minimal backflush losses. Thus – with the KREYENBORG V-type screen changer with power backflush technology – it is for example possible to produce high quality packing straps out of pure PET recycling material with high pollution degrees (e. g. bottle flakes).

For the user this stands for a new level of the economic production. The KREYENBORG Infrared Drum IRD is of special interest for PET recycling. By means of infrared radiation an extremely efficient drying and crystallisation of PET is guaranteed in a continuous process. But in principle it is also suited for the thermal treatment of almost all free flowing bulk goods (e.g. chemical powder, EVA, glass powder, hotmelts,…).

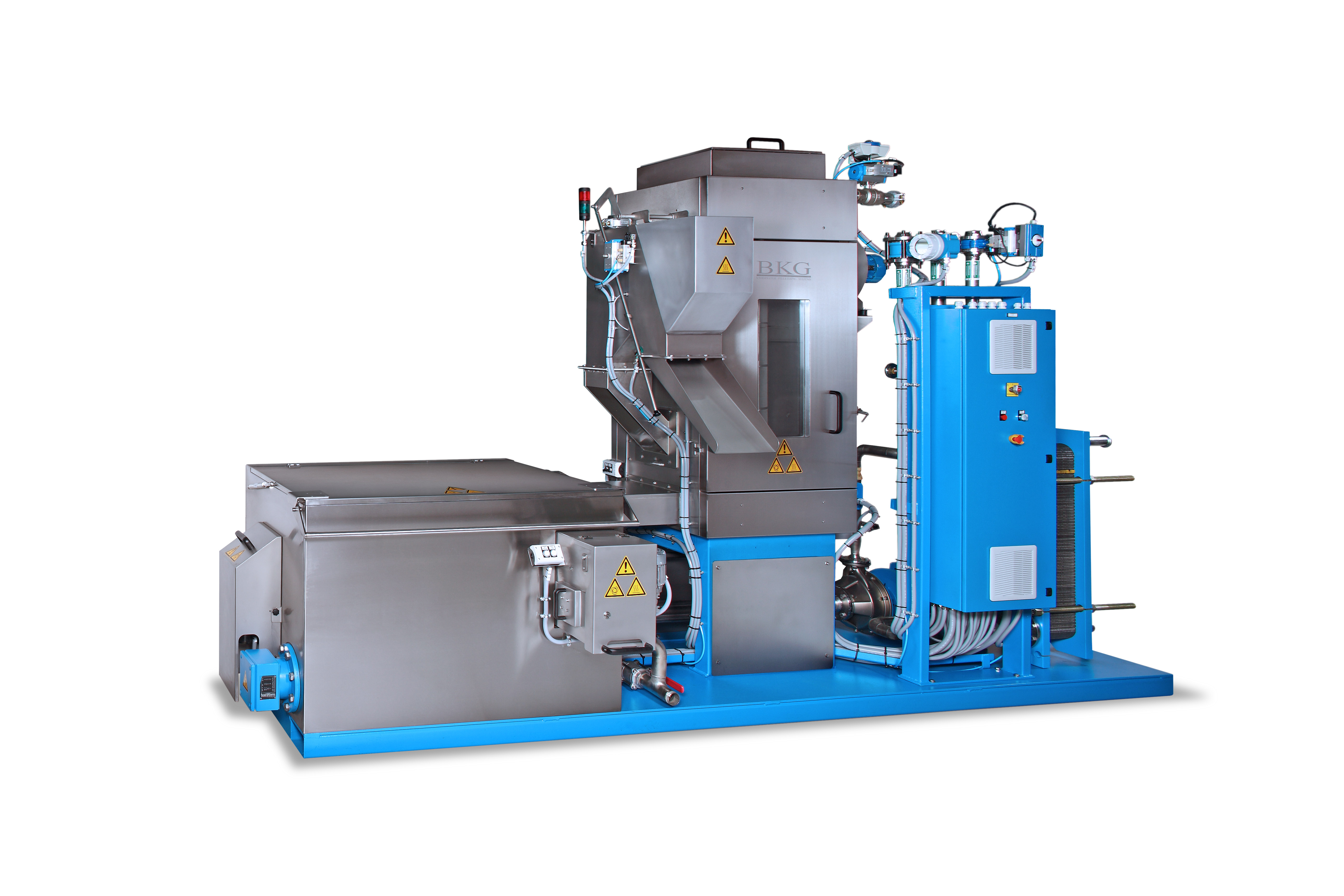

The Underwater Pelletizing Systems of BKG Bruckmann & Kreyenborg Granuliertechnik GmbH have proved their excellence all over the world. These systems are supplied with drying, water system and control ready for use and are suited for all thermoplastic materials, also for the production of micro pellets. Relating to throughput the scope ranges from 2-80 kgs/h (Labline 100) to systems with 35,000 kgs/h. For particularly economic processing of PET, BKG has developed the Inline Crystallization System CrystallCut®. With this system, pelletizing and crystallisation are effected in one process step, without the supply of additional energy.

KREYENBORG Group presents its solutions at Interplastica 2013 in hall FO, stand no. FA49. A pelletizer type Compact 120, an underwater pelletizing system, a melt pump type 70/70-07/MB and a unit that consists of a screen changer type K-SWE-101, a melt pump type 36/36/01 and a diverter valve type 300/25 will be shown.