Very Good evening, today we have Mr Tushar Parikh, Director Neoplast Eng. Pvt. Ltd., Ahmedabad, Gujarat, India

Very Good evening, today we have Mr Tushar Parikh, Director Neoplast Eng. Pvt. Ltd., Ahmedabad, Gujarat, India

Q. Sir I would like to start with your background first. Little bit about your qualification background and work experience.

A: I have done Bsc. with Chemistry and gone through the special Plastic Processing course from CIPET Chennai. Right now I am also involved with academic field. Though I am more in the industry , an academic training is my passion. So, I am connected with an Engineering College as well as Government Polytechnic College, where plastic course is being run in Gujarat. We are organising technical lectures of various Industry Experts for students. I am also very much connected with the Indian Plastics Institute in Ahmedabad Chapter. I usually co ordinate to train the students by Industry Experts.

Q. I would like to know how you started and entered into the field of Plastics?

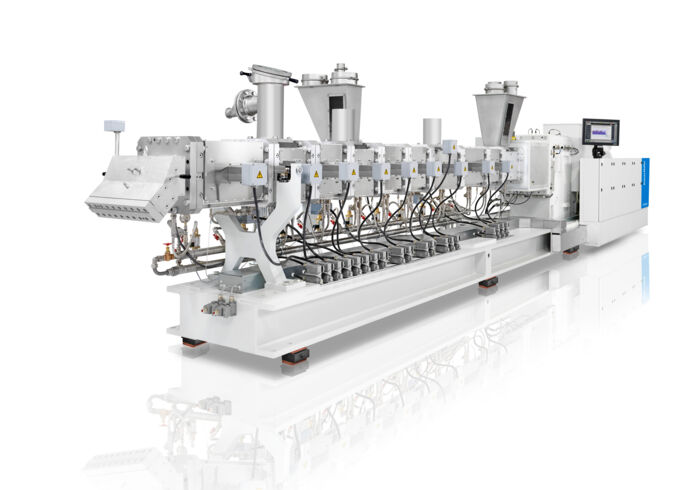

A. The company was started by our elders in 1964 ,initially with Injection Moulding of nylon, specially the parts required by the textile industry in Ahmedabad and its surroundings. Then after over the period they developed extrusion of PVC film which was the replacement of the transparent cellophane paper used by the textile industries and in 1968-69, first time PVC blown film was developed by our company in India. After two three years of this film extrusion business, due to insistance of M/S NOCIL , our elders developed the machine of PVC blown film where the High Intensity Mixer and the Extruder is required. And this is how we entered from the processing industry to plastic processing machine manufacturing sector. Today over the period ,we have expertise specially for PVC compounding line. Seventy percent of the Indian market is being served by our company right now.

Q. What was the key position you were holding when you joined Neoplast?

A. This is sort of a family business . Three friends started the business in 1964. And by default the next generation has to take over the charge. Ours is the third generation and we are working together since then and developing more and more each year.

Q. I would like you to shed some light on the segment of the PVC industry particularly catered by you

A. Well as you know that the PVC is the most economical polymer available in the market. But only thing -PVC is not at all processable directly. So, in early time, there were a few players in the PVC processing industry. But then after as soon as the infrastructure development started to take shape in India, the demand of water distribution has automatically increased. And that is why the PVC pipe is the cheapest media which is being used by the infrastructure industry as well as the agriculture. That is how PVC industry has grown up to very high level. As Neoplast has developed PVC compounding mixers in 1968-70, we got advantage over other competitors. Over the period Neoplast has reached to a level where it is now renowned as a manufacturer of the largest size PVC compounding machines in ASIA with a very high output. Everyday we are pushing one machine out of our production area. And that is how we have even today mantianed sizable contribution in PVC industry, not only in India but also in Asia.

Q. So are there any other domains of the plastics industry catered by you excluding

PVC ?A. High Intensity Mixer is our core product. But now after the development of new high output mixture, the feeding to the mixer was immediate need of the processor. And several years back, the big PVC processors were importing the feeding systems, conveying systems, storage silos and all sorts of related accessories and attachments. So we have developed completely automized feeding system, right from the resin storage upto the distribution of PVC compound to the multiple lines of extruders/ injection moulding lines. Of course, this is all based on the PVC. But other than PVC now we are also in non PVC industry where we produce single screw extruders for master batch manufacturing. We have very good product in our folio is the Lab Testing Equipments. These are very highly précised equipments. Our this range of product is meant for Blown Film testing, filterability, master batch dispersion testing and a big range of master batch testing equipments are available from us. And our major customers for this product are from over seas because our product is the straight away replacement of the International lab equipments. Many Asian polymer universities where plastics courses is being run, are equipped with Neoplast’s lab equipments.

Q. As you shared that Neoplast is the largest player in PVC processing machines manufacturing sector in India. I would like you to share the key hurdles faced by you in achieving this success under your tenure.

A. Well, you know that any progress is never so easy and smooth but the hurdles makes it more strong. Our major hurdle was the Chinese equipments as these equipments were available at a very lower price compared to what we were offering in the market.But this is very common threat to all Indian and developed countries. But since last two -three years, they have proved inefficient after investment due to their inferior quality. So the same customers are now buying from us and we got back good hold in the market again. The hurdle was only from the commercial side. We get many consultants from Europe for up gradation of our existing technology as well as to get new developed technology from them. We are also getting their services even to help our big customers for project expansion . They are giving training to our customers directly so that they can also improve their processing system and of course the quality of their end product.

Q. Any other hurdles like, recently we saw a deep recession time and hard financial years?

A. By God Grace we have come out from that recessive phase. Because we consider that the recession is the right period to develop another new product. So we never took recession time in negative way. We thought that God has given us a golden opportunity to make our company more strong for upcoming time. So we started to develop non PVC products during that time. I would like to tell you that in this time only we developed Under Water Pelletiser. Till time this machine was not developed domestically and today we have under water pelletizer of very high capacity i.e. upto 2000 KG/Hour in our regular product range . This product was developed only in the recession time when we had ample easy time to take the trials at our customer’s place and we had really fun time in recession .

Q. As you have talked about Chinese industry and we have seen lot of exhibitions and developments are going on in the Chinese Plastic industry. Do you think that China is a threat to the India Plastic Industry particularly in the machine manufacturing sector?

A. Well I don’t think so. Though the China has two types of standards of machines. One is with very low price and other is as a substitute of the European product which has higher price tag. But unfortunately in early days when they introduced their products, they have lost the faith of Plastic Industry for them. Today the Indian processor thinks twice and thrice and after reconsidering several times, they finally goes either with a good product of India or another imported equipment but not of Chinese product.

Q. Do you think is there a possibility that few of the high quality German and American machine manufacturers move to China to put up their manufacturing bases for cheaper machines ?

A. Well it is already done, but I will tell you that major of the leading players, I mean plastic processing machinery manufacturers, who are leading in Europe, have already started their factories in China. But the product which is coming out of the China factory, has got some sort of the doubt in mind of their customer. So now they are offering two things again. This is ‘X’ prices for China factory and ‘X+Y’ price for better quality but produced in China and ‘Z’ price for original European make product. By such options, the customer gets more confused as what to take and what not to trust. And not only this, they are again confused & get doubt whether it will be hanky panky if he buy European equivalent standard produced at their China Plant. So they are afraid that whether they will get the real return of their investment or not. So finally they conclude to drop the idea to buy from them .

Q. My other question is more general towards Plastics industry of India. Do you think government of India is taking good enough steps to support the Indian Plastic Industry?

A. Whole economy of India is booming up. So the plastic field is growing & developing by default. Of course there is a threat, from the common society about the environment. But, now the plastic industry has also started to take the very strict actions to control this pollution. To my opinion it is only due to the un-disciplinary act of the user itself. When you use any disposable plastic, then its proper disposal is your moral responsibility and the discipline has to be maintained at the time of its disposal. So whatever we are looking around on the streets or roads, it is only the un-disciplinary acts of citizens themselves. Otherwise, per capita consumption of plastics in India is very very low compared to of developed countries. And when we go to the developed countries, we come across lot many type of plastic packaging, but you never see the un discipline in the disposal of plastics. And that is why plastics has earned little bad name in India. We used to say that there are five basic natural elements God has given to this earth- Earth, Water, Air, Fire, Light -but now I say that we have now six basic elements and the sixth is plastic as plastic is the substitute of metal and lot many other things. So we are saving the nature by using plastics. Only the discipline is to be maintained, that is it.

Q. As you are related closely with plastics academic institutions. Do you believe there is a gap between the technology skill set which is required in the industry to the type of skill set available in the market today?

A. Yes you are very true. The way plastics industry is progressing, similarly technical quality of the engineer needed by industry is not there. There is a big gap. I am one of the active member in advising for Education Policy of Gujarat state itself and also connected with many academic institutes where we are demanding to increase the seats of polymer engineering, whether it is diploma or degree course. Gujarat is producing 70% of the total domestic polymer production and we have insisted and requested the Government to increase the seats in polymer engineering in self finance colleges as well as Government institutes. Presently there is a large difference between the demand and supply as far as the intellectual and skill set is concerned in our field. Lot many oppertunity is there for the plastic engineers in Gujarat as well as in India.

Q. As you shared that we as a country are far behind the average world consumption of plastics. But as the plastic of petrochemicals are fluctuating and the monopoly we see in India for major polymer products. Do you think it could be a barrier in growth somehow ?

A. No I don’t consider this thing as barrier. Because now days the import policy of Government of India is very much easy. And people have started forming clusters at association level. In that cluster ,a processor is registering his monthly requirement of Polymer & accordingly the association will book it. Association has started now to take the interest to feed the raw material to its members. So a collective booking process has already taken place. Other than the local polymer manufacturing company, now very large companies of the world are now setting up their own offices in India. They are now booking the order well in advance in bulk quantity and passing attractive quantity discount to said association. Then after the small processor is also able to compete with large processor. Suppose small processor of 50 MT per month is a member of that cluster where association is importing 3000 MT – 4000 MT at a time , is now getting his polymer at a price advantage which other large size processors are getting. So the monopoly is now not much concerned in this sort of dealing now.

Q. Would you like to suggest any change in rules,regulations or policies of government of India which can make the path sustainable for the growth of Indian Plastic Industry ?

A. Of course. Any framework and policy of the government has to be applied firmly for a longer time. They say that the policy is meant for five years. But every year in Feb.-March we are afraid that the policy of exim will change or not. And they keep putting some sort of restrictions on some & some product. This is a problem. So as an industry we cannot make a long term plan. So what happens, suppose some one is investing a very huge amount of plant for some product but after a year or two, if that product goes into the restricted import list, then his investment is zero. So any new investor is always thinking twice or thrice, because they don’t know about government policy. Moreover the rate of the duty/ taxes, whether it is import duty ,whether it is excise or whether it is a VAT. It changes so fast that for long term commitment with the buyer -specially in the international market is not possible. Because when we go to the international business, they want a commitment at least for running year or next calendar year. At that point of time, we are afraid that if Government will impose some duty or some policy will be changed then there will be a great problem of execution of order. So one cannot do the long time contract internationally. That is a serious problem faced by the industry.

Q. Any two or three key segments in the Indian Plastic Industry you would like to suggest where high possibility of growth exists?

A. The agriculture industry. If you go to Israel you will find that with the help of lot many plastic products, they are today cultivating the crop. This is the world number one country where the cultivation output of the crop against the area of the land is few times more than any developed country. In one square meter of the agriculture land their output of crop is very very high compared to other countries of the world. So that is always done with the help of plastics. They have developed lot many things. They have developed special type of mulch film, which maintains specific temperature, humidity or several climatic condition which is ideally necessary for that crop. They also do drip irrigation, using plastic system where water is used in very controlled way. A certain drop of water is being given at a certain time so the crop gets cultivated more. So this all is possible because of plastics. So in agriculture, there is lot of improvement which is also possible in India and lot of growth can be achieved. Similarly Infrastructure. Here unfortunately very few Plastic things are used though a lot of possibility is there. Because in foreign countries almost 20-30% plastics of total building material is used, though in case of India you will not find it. Even the entire windows, doors , partitions is used of plastic profile now a days. So that possibility is also there. To my opinion, the infrastructure and agriculture can be right field where lot many exercise is yet to be done by plastic industry.

Q. Would you like to suggest any changes in the current scenario of Indian Plastic Industry to help new entrepreneurs to enter this industrial sector?

A. Yes. This is a right time to develop Bio Degradable plastic. It is now high time as the society now badly needs it. The second thing as I mentioned earlier is about awareness which is to be created in the society very aggressively , so that the disposal of the plastic should be done in a disciplinary way . if it will be implemented than automatically , people will love to use the plastic products extensively. And the third thing is – recycling of plastic. Because recycling business is looked as a cheap business, but to my opinion maximum opportunities is lying in recycling business and most of the plastics today can be recycled. And certain laminates which cannot be recycled, one of the scientist has already developed technique to de-laminate such webs. And we are also developing a machine where such type of multi polymer laminated plastic can be de-laminated and separated and then further recycled. That time is very near now.

Q. In the last I would like to have your vision for Indian Plastic Industry in 2020.

A. I think big companies have already started with 2015 vision, 2020 is yet far. But in 2020, the per capita consumption of the plastic is expected four times than 2010. So an ample of growth is expected to take place in coming 10 years time i.e. 2020. Many European and American companies have started to pay attention to the Indian processors and the Indian processor has also now started to adapt the new developed systems. There was a time in industry, when processor was thinking that my father has given me this machine, so I had just to maintain to keep it running and I am supposed to take my production out of that machine only. But now the new & intelligent generation has come. They think about Energy Saving, Labour Saving, Better Quality Product etc… So now they are putting up high output machine of new upgraded technology where everything will be added together. So when this type of mentality is existing in the field, then sir, I don’t think that our expected growth about ten times is beyond reach.