- CHOMARAT wins a JEC Innovation Award in the carbon category thanks to C-PLY Bi-Angle™

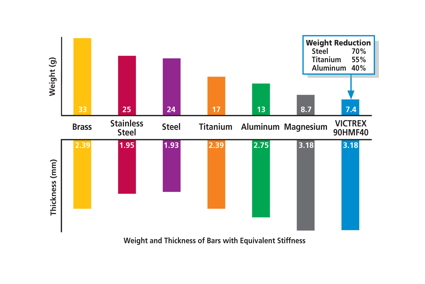

- C-PLY Bi-Angle™ is a carbon reinforcement allowing the production of composites 30% lighter than traditional carbon fiber composites

- CHOMARAT will be present at JEC Americas show in Boston, stand E34

The current market demand for weight reduction is related to both environmental and performance requirements worldwide. In response, CHOMARAT has developed C-PLY Bi-Angle™ in partnership with Stanford University (USA) Department of Aeronautics & Astronautics and Hanyang University (Korea) Department of Mechanical Engineering. It consists of an unbalanced thin ply bi-axial carbon reinforcement (non-crimp fabric or NCF) contributing to both weight and composite processing cost reductions. C-PLY Bi-Angle™ delivers superior mechanical properties offering new opportunities to create unique composite solutions in numerous sectors, including Automotive, Wind Energy Components, Sports & Leisure products, tube and pipe products.

A THREE-STEP MANUFACTURING PROCESS FOR LIGHTER, CHEAPER AND TOUGHER COMPOSITES

The process includes:

– Spreading: achieving an individual ply weight of 75g/m² requires a skilled proprietary spreading process consisting of laying the yarns flat and straight with uniform tension before spreading them to form a ply that is uniform in fiber dispersion, weight, width and thickness.

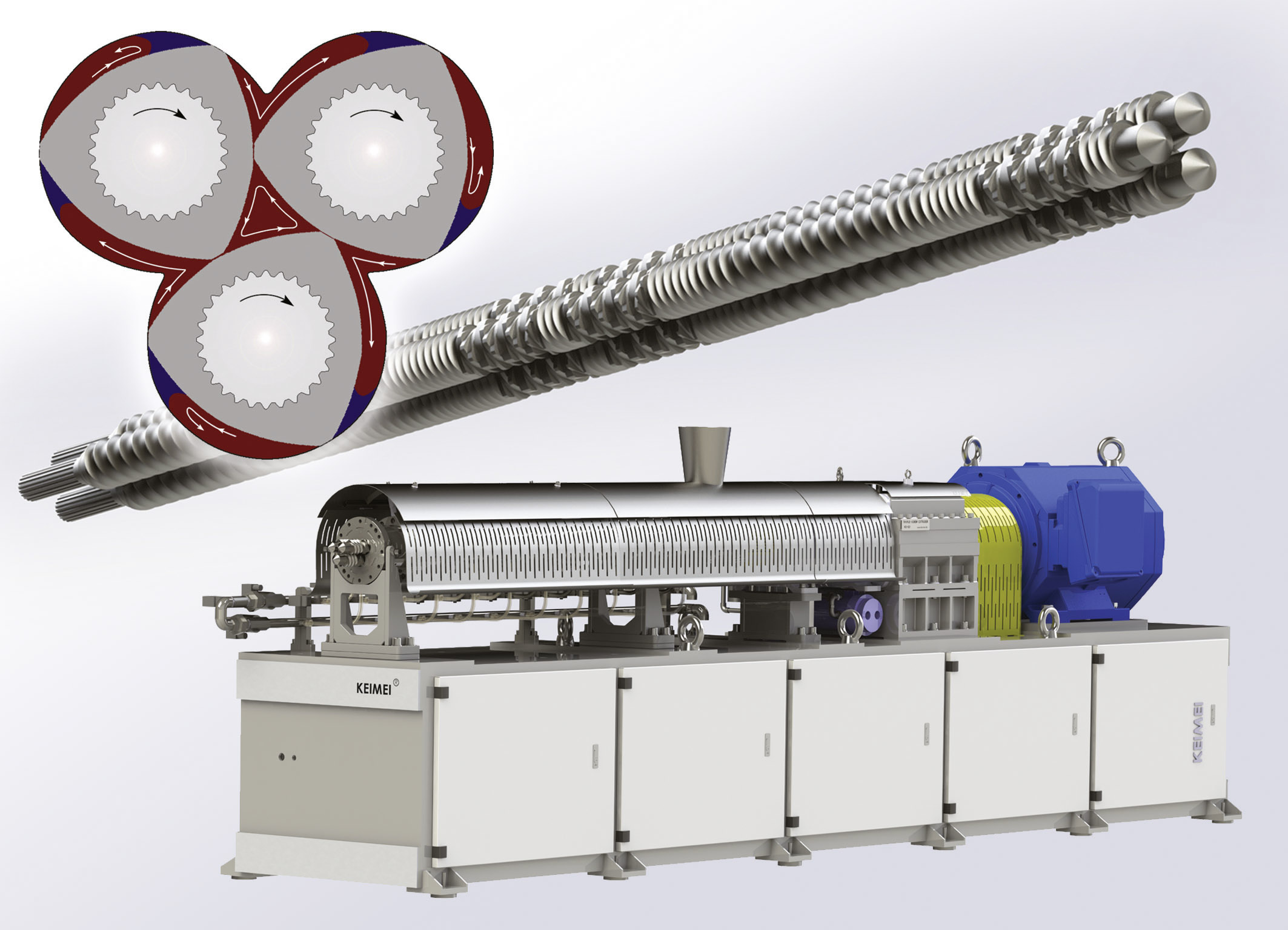

– Ply forming: performed on a multi-axial machine, but instead of laying down the yarns as in the standard technique, UD plies are placed on top of one another in the desired directions. Obtaining shallow angles (20-30 degrees) required the design of new machine kinematics.

– Combining: this final step ties the plies together and consolidates the fabric laminate. It is based on a very fine stitch designed to reduce the impact of foreign materials and the creation of voids to the largest possible extent.

The use of C-PLY™ with an asymmetrical construction (0/Ѳ where Ѳ ranges from 20 to 30 degrees) results in laminate values that are impossible to achieve with unidirectional plies that have quasiorthotropic angles (0, ± 45, 90 deg.).

THE FIRST ULTRALIGHT BICYCLE FRAME PRODUCED USING C-PLY BI ANGLE™ WILL BE DISPLAYED AT THE JEC BOSTON SHOWCASE

American Artisan Bicycles is the first carbon bicycle manufacturer to use CHOMARAT’s C-PLY Bi- Angle™ Carbon NCF to produce innovative carbon road racing bicycles in the USA. C-PLY Bi-Angle™ is key to producing carbon frames under 800 grams without strength compromises, while maintaining excellent ride characteristics.

ONCE UPON A TIME…

It all started in October 2010 when Michel Cognet, Chomarat Group managing director, met Professor Steven Tsai and Professor Sung Ha at JEC Asia. In this meeting came the idea to incorporate the new composite laminate they were developing into a multiaxial product form. Chomarat readily accepted the challenge to convert a mass-production tool into a unique manufacturing process for a new range of multiaxial materials, and therefore committed to turning Professor Tsai’s theory into an industrial reality.

One year later, the first tests carried out on different processes (prepreg, pultrusion and resin film infusion) have met and exceeded the theoretical expectations. C-PLY™ is suitable for all lamination techniques, including hand lay-up, LRI, RFI, RTM, VARTM and prepreg. It can be used with all types of fibers including carbon, E-glass, S2-glass and aramid.