- International: around 170 participants to a webinar on fibre-direct compounding (FDC)

- Future technology: online event examines innovative FDC process from all angles

- Skill sharing: expert lectures from Arburg and industry and scientific partners

On 8 July 2021, around 170 participants from around the globe took part in a special Arburg webinar on Fibre-Direct Compounding (FDC). Experts from Arburg, a pilot customer and materials and process partners outlined the benefits of the innovative FDC process and the factors that should be taken into account in order to efficiently manufacture long glass fibre reinforced lightweight construction components. Interactive surveys and live chat discussion rounded off the online event.

“The FDC process is a pioneering technology that provides solutions to three equally important trends: innovative, lightweight construction, reduced unit costs and sustainability,” explained Manuel Woehrle, lightweight construction expert and Team Manager Technology Sector Sales at Arburg, in his talk. He explained the function of Fibre-Direct Compounding and the advantages of using this lightweight construction process over the processing of long fibre granules; including a larger selection and cheaper price of material, more flexible fibre length and behaviour, as well as customised component properties. For this reason, technical plastics can also be substituted alongside long glass fibre materials. Other benefits are a smaller carbon footprint and the possibility of upcycling. This is especially important where the use of recycled materials is required. Using a variety of components as examples, Manuel Woehrle demonstrated how fast a new FDC system achieves a return on investment and how component costs are reduced.

Customer, material manufacturer and partners share their experiences

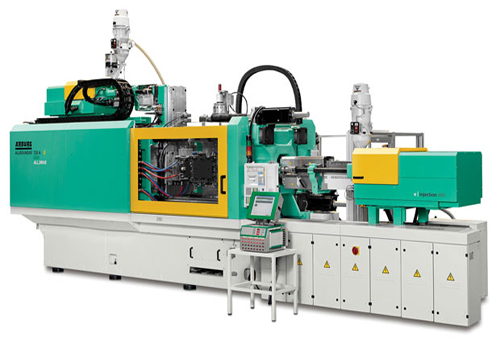

Ruediger Braun, Managing Director of Krug Kunststofftechnik GmbH, recounted his ample experience as a pilot customer of the FDC process. The company has three Allrounders with FDC equipment in use, now fully automated and producing long glass fibre strengthened components for the automotive sector on a large scale.

Arburg developed the FDC process with scientific support from the SKZ – The Plastics Center. Christian Deubel, a consultant at SKZ – KFE gGmbH, commented on the foundations of fibre length analysis and important indicators. He also demonstrated how mechanical properties differ depending on the point at which they are sampled, and how this can be specifically influenced by means of FDC.

Markus Kralicek from Borealis Polyolefine GmbH, explained which factors are particularly important to the material manufacturer, describing the advantages of fibre-reinforced PP and presenting several types of materials and their areas of application. He also revealed the impact of additives on compounding and gave important guidance on how to configure components and tools.

Dany De Kock of Johns Manville Europe GmbH gave a presentation on the manufacturing of various types of glass fibre rovings and their specific characteristics when it comes to direct processing. Lastly, Frank Fischer, Senior Applications Manager Fibre Direct Compounding at Arburg, showcased fibre length analyses and mechanical tests for the different areas of application. Using numerous examples, he clarified the broad application range and high potential of the FDC process.